Calibre interview: Iain Chalmers, MD of Affinity Flying Training Services

The Royal Air Force (RAF) has been the leading operational service and often the most visible kinetic element of the UK’s foreign policy for some time now. Every pilot that climbs into a Typhoon and taxis down a runway to engage a target, be that in Yemen or Syria, will have been through the UK’s pilot training pipeline. This starts with basic training, often in a civilian aircraft operated by a company called Affinity Flying Training Services. Calibre Defence met with Iain Chalmers, managing director of Affinity to learn more about the company and the role that the company plays in getting pilots to their Typhoons.

Affinity, built for delivery

Iain Chalmers, MD of Affinity Flying Training Services. Iain served in the RAF and has been MD of the company since it was established. Credit: Affinity Flying Training Services.

Affinity Flying Training Services is a joint venture of Elbit Systems UK and KBR, it was set up in 2016 specifically to become a key partner in the UK’s Military Flight Training System (MFTS). MFTS was set up to provide a single training pipeline for fixed and rotary wing pilots across the RAF, Royal Navy, and Army Air Corps. The company is responsible for delivering and maintaining a fleet of 42 training aircraft to Ascent Flight Training, which delivers physical and simulated training under the MFTS. “Affinity effectively operates as an SME [small- and medium-size enterprise], even though we are part of Elbit and KBR,” Chalmers said during a call with Calibre Defence in February 2025. This drives a number of considerations for the company, especially when it comes to people. “As an SME, it’s about having the right, good people in the business who are focused on delivery. We also need the right manpower mixture, we probably have more licensed engineers per aircraft than others, because we are in a training environment, they like the aircraft to be as perfect as possible,” he explained.

This has not always been the case, Affinity started out with a greater number of avionics engineers, reasoning that the Texan flight training aircraft would require more frequent maintenance on its electronics and flight systems. “We actually needed more airframe engineers as the students like to land them in a certain way,” Chalmers said. Ultimately, as is the case for any SME, having the right mix of people is the difference between success and failure. Affinity, with its staff of 200, does seem to have hit that balance, “we have a dispatch rate of around 98%, and if you look at the Texan, which is a military trainer, we get about a 95% dispatch rate,” he added. Maintaining the right people is as important as maintaining the Affinity fleet, with engineers requiring around 12 months of experience to learn all of the different snags and peculiarities of the aircraft.

Dispatch rate is key to maintaining a pilot training pipeline. The windows for take-off can be limited, especially for new pilots, so every flight that is missed because of technical faults can delay the progression through training. “A key element in the end result is being able to turn pilots and competent trainers around in a fast and efficient time frame. It’s probably a couple hundred hours to qualify a student and this means Affinity has a big job to do in keeping the aircraft flying,” Chalmers explained. He continued to explain the challenges around maintenance, as Affinity maintains the fleet of trainer aircraft, it has its own relationships with the manufacturers of its aircraft, the Grob 120TP from Grob Aircraft in Germany, the T-6C Texan II from Textron Aviation in the US and Phenom 100 from Embraer in Brazil. This approach, which was built to deliver on the company’s MFTS contract, has produced over 70,000 flight hours since 2017.

Supply challenges

“We have good OEM relations, there are over 1,000 Texans flying in the world now and they have a lot of data. We use that data to put together an aircraft maintenance plan that’s approved by the Civil Aviation Authority (CAA).” This data, combined with Affinity’s own, allows for predictive maintenance – the MFTS contract runs until 2033, and the company has planned its maintenance schedule all the way out to that date. “It will change dynamically of course, but we are already in conversation with our suppliers to secure long lead time items and repairs.” Some of those items have 24 month lead times, a hangover of the disruption to global supply chains caused by COVID, he added. “If we don’t get that bit right, we might lose flight hours,” Chalmers said.

COVID is not the only confounding factor in the way that Affinity works. As the UK left the European Union, the CAA has had to step in and provide the services and capabilities that were held under the EU. “The CAA have had to stand-up the design and certification organisation, and they are still building that organisation up,” Chalmers explained. “We have also seen some changes to CAA policy, that mean for example we can’t accept components that have been repaired elsewhere and brought back into the UK.” The impact of this is quite profound, but not in the way you might think. Affinity has the engineers to repair engines and in any case, big things like engines are not the challenge. “It’s never the big things, it’s always the small widgets that are made in a small firm that makes components,” Chalmers said. The CAA requires companies to meet its certification requirements, not typically a challenge for large companies making parts that are shipped around the world, but a real hurdle for the widget makers.

“This means that I have to buy new, rather than repaired, which is an issue because more and more contracts are being let under a civil-military construct, so the costs could potentially increase,” Chalmers explained. Why is this a problem? Because it would ultimately increase costs for the taxpayer. If you have ever bought a new phone, consider the cost of that new phone – typically more than £1,000 – compared to the cost of a repaired phone, which may be less than half the price. This is how the CAA regulations, while necessary, could impact the costs of the UK’s flight training pipeline.

The Affinity fleet

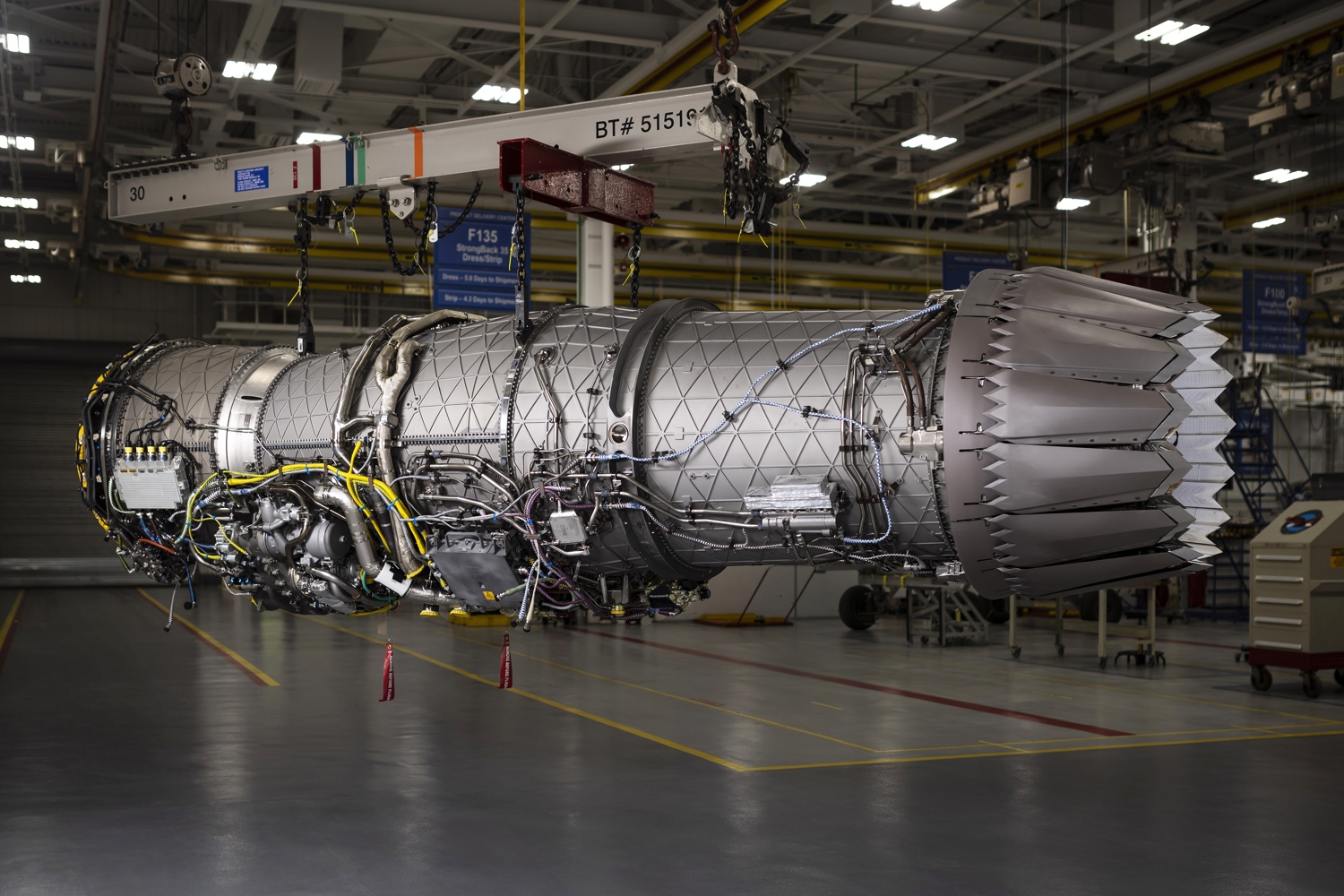

The Affinity fleet includes the Texan advanced trainers shown here, as well as the Grob 120T Prefect, and the Embraer Phenom 100, which is in the featured image at the top of the article. Credit: Affinity Flying Training Services.

Affinity has bought and brought into service 42 aircraft across three types; the Texan and Prefect noted above, and the Embraer Phenom 100. The aircraft are divided between RAF Cranwell, RAF Barkston Heath in Lincolnshire and RAF Valley in North Wales, with the Prefect fleet of 23 aircraft primarily located at RAF Cranwell and RAF Barkston Heath. “At Cranwell you have people that haven’t flown before. So, they need time and space to learn and train, which means they need a volume of aircraft,” Chalmers explained. The Prefect is a side-by-side trainer aircraft powered by a Rolls Royce M250 turboprop engine. It can fly at a top speed of 450 km/h (282 mph) and up to altitudes of 7,600 metres (25,000 feet). The aircraft is designed to provide beginner pilots with an initial flight experience, but allow progression to handle spinning, stalling, and aerobatic manoeuvres, handling forces from -4G to 6G.

After training at RAF Cranwell, learner pilots move to RAF Valley, where they transition to the Texan and eventually the Hawk, a jet engined advanced trainer provided by BAE Systems. They learn how to fly in formation and to operate with the Texan. “At Valley, on the Texan and Hawk, you’re closer to the frontline in terms of learning air administration, flying as a sortie and so on. Some of it is because the aircraft go faster and are more complex, so they have to learn more about how to use them,” Chalmers explained.

The Texan is another tandem two seat trainer designed for pilots who will take up a combat air role – air superiority operations, close air support, and the like. It is also powered by a turboprop, this one the PT6A from Pratt and Whitney Canada, and can fly at altitudes up to 9,400 metres, reaching speeds of 585 km/h (364 mph). Like the Prefect, it can sustain manoeuvres from -3.5G all the way up to 7G, and is designed to enable pilots to practice combat manoeuvres like high banking turns and tail chasing. It also comes with an ejector seat and heads up display, making the cockpit experience much closer to the one that pilots will find if they successfully complete their training. “The Texan is much closer to a frontline jet so you have all the trappings of a frontline pilot, the face mask, the g-suit, and the oxygen etc.” Chalmers said.

Looking ahead

Affinity is primarily delivering the MoD’s MFTS programme at present, “but we have been bidding other public sector contracts and we’re looking to develop other capabilities,” Chalmers said. Notably, this is partly driven by the company’s team, “they want to see what else they can do, and if I don’t do more, they will go somewhere else. That is part of the deal of being an SME sometimes, but I’d rather give them other opportunities to progress,” he said. “If MFTS is rebid in 2033, we will of course bid for it, we are after all an aviation services company” Chalmers explained.

Calibre comment

Affinity Flying Training Services is another example of a UK SME that is able to consistently meet MoD contracts to a very high standard. It has shown that a purpose-built organisation can provide capabilities and scale them as needed. However, the environment for SMEs in the UK is challenging; few are given long-term contracts in the way that Affinity was in 2016, and must instead rely on their ability to secure year-to-year income. This makes it difficult to diversify their income stream and innovate or develop new capabilities. Some turn to a blended approach between the commercial and defence world, as is the case with Fering and Flarebright, and now also for Affinity. The dual-use approach can also encourage venture-capital firms and investors to fund those companies, which in turn helps the MoD by ensuring they are available when they are needed.

By Sam Cranny-Evans, published on 25th March, 2025.

Sign Up for Updates!

Get insider news, tips, and updates. No spam, just the good stuff!